By Ding Zhijun, People’s Daily

Mining is getting intelligent in Ordos, a city dubbed “Coal Capital” in north China’s Inner Mongolia autonomous region.

The city, which is home to hundreds of billions of coals underground, produced 670 million tons of coals last year and has been the top coal producer among all Chinese cities for years.

Intelligent mining technologies are constantly upgrading the production models of local mining enterprises, assisting them to lower production costs and expand benefits.

For instance, in the Madiliang coal mine in Ordos, there is almost no trace of coals in the main mining area, apart from several trucks waiting to be loaded in the outbound area.

The Madiliang coal mine, producing 8 million tons of coal annually, is only medium-sized in Inner Mongolia autonomous region.

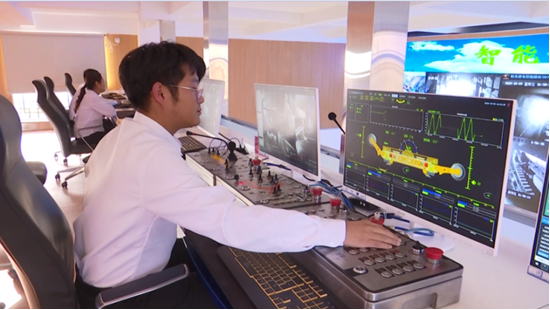

Today, with a digitalized and intelligent system, staff members working at the coal mine can start machines and transfer extracted coals onto convey belts with just clicks on a mouse.

Tian Dongying, a mine worker who started working in 1993, had experienced the era when mines were dug with shovels. Nowadays, rather than going down to the shaft, he only needs to solve technical problems on the ground.

“I’ve been mining for half of my life. I never thought that mining could be turned into office work someday,” said Tian.

“Mining today is basically done through remote control, and workers go down to the shaft only for equipment maintenance, which has significantly reduced safety risks,” said Wu Jinsong, who’s in charge of the Madiliang coal mine.

Intelligent mines are built to allow devices to work for humans through technological means to minimize safety concerns, said Wu, who has been working for over three decades at the Madiliang coal mine.

Thanks to a whole-life cycle device management mechanism, a digital control system and an intelligent mining system, the coal mine has achieved efficient and low-carbon operation. Its operational cost has been reduced by more than 30 percent.

In early 2020, there were only 110 workers on duty at the coal mine due to the sudden outbreak of COVID-19, but it still achieved its output target of 18,000 tons of raw coal per day.

Many coal mines today are facing labor shortages. However, because of the intelligent technologies applied, the Madiliang coal mine is very attractive on the job market, especially for young job-seekers.

“The improved production efficiency creates a better work environment and proves that coal mining enterprises can also be tech-ish. We are all confident about our future,” said Lian Jiayu, who came to the coal mine in 2019 after graduating from university.

The Madiliang coal mine is a miniature of Ordos’ efforts to advance intelligent mining, said Li Li, Party secretary of Ordos.

“Intelligent coal mining has been promoted at all newly constructed coal mines in our city during the past five years. We hope to bring the convenience and benefits to more and more mine workers,” Li told People’s Daily.

Intelligent coal mining is an unavoidable path for the mining industry, and the experience of intelligent mining companies is shedding light on more and more coal mines, said Wang Jinbao, head of the energy bureau of Inner Mongolia autonomous region.