By Song Haoxin, “Selling bamboo earned me a net profit of around 200,000 yuan ($27,987),” said bamboo grower Li Kaiming from Tianchi village, Qingshen county, Meishan, southwest China’s Sichuan province, while harvesting bamboo that had just matured.

These bamboo were later sent to a bamboo industrial park 15 kilometers away, where they were processed into bamboo pulp paper. The paper manufactured in the industrial park now holds a 30-percent market share of natural-color tissue paper in China.

As the use of plastics is gradually replaced by bamboo, the industrial park is working to establish a new production line of mulch made from bamboo fiber to seize market opportunities.

Recently, a three-year action plan on promoting the substitute of plastics with bamboo was jointly released by China’s National Development and Reform Commission and other departments. This has presented new opportunities for Sichuan, which ranks second in China in terms of bamboo forest area, to strengthen and extend the chain of the bamboo industry.

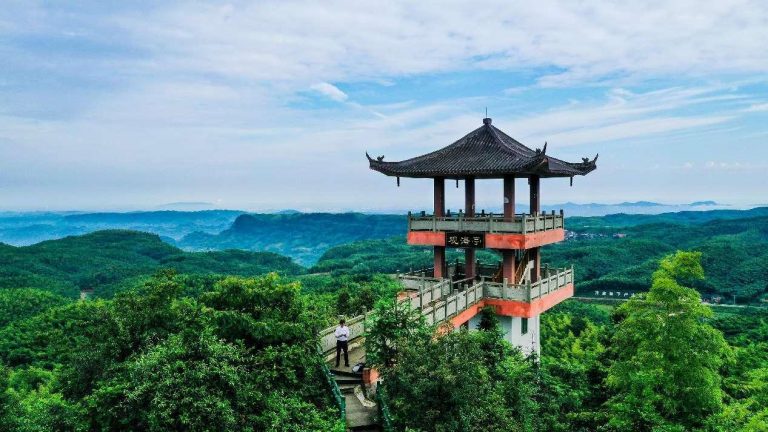

“I was so busy! I never thought that bamboo-related tourism would be so popular,” said Nie Zhijun, head of the collective economic organization of Zhaoping village, Baijie township, Naxi district of Sichuan’s Luzhou, referring to the tourist boom at a bamboo culture attraction in the village during the Mid-Autumn Festival and National Day holiday

It was the first long holiday since the attraction opened, and its business volume more than doubled, according to Nie.

The integration of the bamboo industry and cultural tourism has brought benefits to the Naxi district, prompting it to launch 20 provincial-level cultural tourism programs that cover rehabilitation, nature education, floral parks, and many other sectors. Tourists flock to the Naxi district almost every holiday and weekend.

Taking advantage of this momentum, Naxi has gradually developed a circulation of the bamboo industry in which it grows and processes bamboo, as well as farms and feeds poultry in bamboo forests. Bamboo fungus, black fungus, herbal medicines, and chickens are cultivated in bamboo forests to bring extra income to farmers.

“It is important to ensure that the people engaged in the bamboo industry can truly get rich,” said an official in Naxi. According to the official, more than 34,500 mu (2,300 hectares) of under-forest cultivation and breeding bases have been established in the district, and the output per mu is expected to increase by over 4,000 yuan.

Statistics show that the total area of bamboo forests in Sichuan province stands at 18.35 million mu. However, the province has long suffered from low bamboo yield per unit area.

There are two main reasons for this. Firstly, about 2 million mu of bamboo forests were low-yield and low-efficiency forests, with poor varieties and insufficient irrigation facilities, resulting in slow growth of bamboo. Secondly, the lack of well-developed transportation and other infrastructure leads to high logging costs, making farmers unwilling to harvest.

According to the Sichuan Forestry and Grassland Administration, 1/3 of the bamboo in Sichuan was left unused every year.

“By building roads and standardizing plantation bases, the labor cost for bamboo harvesting can be reduced by half,” said an executive of a state-owned forest farm in Guang’an, Sichuan province.

The forest farm divided its 2,250 mu of bamboo forests into 15 small sections, standardized spacing, and built operational pathways, thus gradually making mechanized bamboo harvesting possible.

“In the past, a worker could only harvest 1 ton of bamboo per day, but now, with the help of machinery, the number is lifted to 6 to 8 tons,” said the executive.

In October 2023, Renhe township in Jiang’an County, Yibin, Sichuan province launched a train for transporting bamboo, which has reduced labor cost per ton of bamboo by 80 percent and made unharvested bamboo forests useful.

To promote the substitute of plastics with bamboo, it is necessary to develop new technologies in bamboo processing and expand new scenarios for bamboo applications.

In 2018, Xingwen County of Yibin developed over a thousand types of bamboo products for hotels, restaurants, long-haul transportation, and home furnishing. It also established China’s first comprehensive trading platform for bamboo-made daily necessities.

On Nov. 14, a bamboo technology firm based in Guangyuan completed tests for a clean and environmentally friendly fiber production program that was led by its chief engineer Qiao Guanfang. This program will soon be put into trial operation.

Thanks to new techniques employed, no wastewater will be discharged during bamboo fiber production, and each fiber produced is as strong as two in the past. Recently, Sichuan province issued relevant policies to promote the development of the bamboo industry. These policies further emphasize the need to strengthen technological support and initiate extensive research on the production of bamboo products for daily use, to substitute