By Li Xinping, People’s Daily

As Chinese elements caught the eye at the just-concluded 2022 FIFA World Cup held in Qatar, a good number of brands owned by China’s small and medium-sized enterprises (SMEs) drew wide attention for their contributions to major venues of the world-class sporting event.

Among these SMEs, Avant Sports Industrial Co., Ltd., a sports facility provider based in Shenzhen, south China’s Guangdong province, provided bleacher seats for stadiums where the World Cup matches were staged. The seats are not only retractable but also can be moved and disassembled as a whole.

Jiangsu Future Lighting Group Co., Ltd. a lighting equipment supplier in Yangzhou city, east China’s Jiangsu province, provided the Qatar World Cup venues with road lamps that integrate multiple functions and can serve as lamps, charging piles, and 5G base stations and can be used to monitor the environment.

China Green Container Co., Ltd., a container house manufacturer in Guangdong province, provided 2,000 container hotels for the Qatar World Cup. Each of the container hotels can be assembled by four workers in four hours.

Jiangsu Tianhong Science and Technology Industrial Park Co., Ltd., a company engaging in the manufacturing, processing, and sale of metal and non-metallic materials in Suqian, Jiangsu province, won the bid to provide highly flame-retardant aluminum plastic plates for Al Janoub Stadium, one of the venues for the Qatar World Cup.

The products of these Chinese SMEs, which boast high quality and the integration of sci-tech achievements, have presented a new image of Chinese manufacturing.

SMEs constitute a large part of a country’s manufacturing capacity. Featuring a huge number and wide involvement in various industries, SMEs exist in different segments of industrial chains. If SMEs can develop unique competitive advantages, they can not only enjoy continuous popularity in markets but become “hidden champions” with great competitiveness in their respective industries and play a greater role in industrial upgrading by improving the short slabs of industries.

Chinese SMEs’ outstanding performance at the Qatar World Cup is believed to be the epitome of the continuous improvement and upgrading of the country’s manufacturing sector.

Industrial upgrading can be a daunting and complex task. In particular, SMEs, which often have limited resources and capital and lack experience in risk prevention, need help to realize transformation and upgrading.

In an effort to improve the SMEs’ weak links, various authorities across China have continuously adopted innovative measures. From releasing a to-do list for solving problems hindering the development of enterprises that use special and sophisticated technologies to produce novel and unique products, rolling out measures to improve the competitiveness of SMEs, to implementing an interim system for the cultivation and management of high-quality SMEs, China has vigorously supported the growth of SMEs and improved their growth environment to help them grow into industry leaders with unique competitive advantages.

SMEs are more motivated to sharpen their strengths, as they are willing to invest and bear hardships.

Shenzhen Moldbao Technology Co., Ltd., a company based in Shenzhen that specializes in digital services related to molds and precision parts and components, has helped more than 50 percent of the core enterprises in China’s electronic information industry innovate products.

“Molds are referred to as the ‘mother of industry’ in the manufacturing sector. We have spent 20 years building a database with a cumulative total of more than one million pieces of information about precision manufacturing processes, solving problems concerning the manufacturing of molds, including low output, slow delivery, and heavy reliance on manpower,” said Cheng Yafei, founder, and CEO of the company.

XGimi Technology Co., Ltd., a smart projector provider based in Chengdu, the capital of southwest China’s Sichuan province, has become a leading company in China’s smart projector industry after nearly 10 years of continuous efforts in research and development.

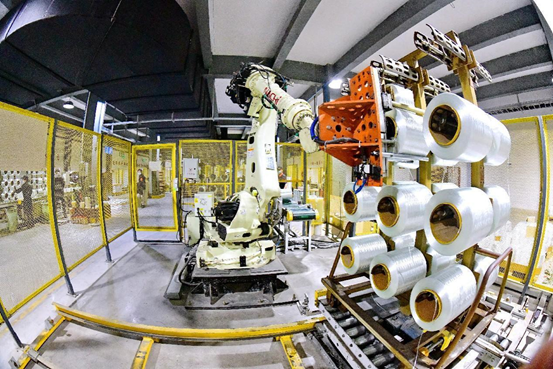

Guangzhou MINO Equipment Co., Ltd., a high-tech enterprise in Guangzhou, the capital of Guangdong province, has persevered in pursuing technological breakthroughs even in the face of a shortage of funds. Eventually, the company has become one of the top-ranked suppliers of intelligent manufacturing solutions for automobile enterprises.

As of the end of 2021, China had 4,762 national-level “little giant” companies, or leading SMEs that specialize in niche sectors, command a high market share, and boast a strong innovative capacity and core technologies.

More than 50 percent of these companies invest over 10 million yuan ($1.43 million) in research and development a year; more than 70 percent of them have over 10 years of experience in their respective industries, and the research and development spending intensity in more than 80 percent of them has reached 10.3 percent.

It is with incredible firm resolve and ambition that SMEs in China have achieved breakthroughs and won the recognition of markets.

China is home to more than 48 million companies. Among them, more than 99 percent are SMEs, which are the backbone force of the country’s manufacturing sector.

It’s believed that the joint efforts of the government and enterprises will give a strong boost to the high-quality development of the country’s manufacturing sector and help more Chinese brands stand out from their competitors on the international stage.